History of the Hocking Valley Brick Industry

( transcribed by Sandra Mitchell Quinn from the 1968 Parade of the Hills Lions Club booklet, by Rev. John Lloyd Evans)

History and photos presented here for educational and historical value.

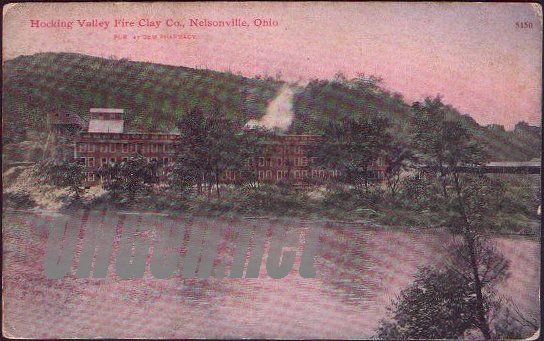

(Hocking Valley Clay Co. Nelsonville photo postcard from files of Sandra Mitchell-Quinn)

Prior to the year 1800 the Ohio territory was engaged in strife so that constructed buildings, in many cases were soon destroyed by fires and by enemies to discourage habitation by the Indians as well as the whites. Chief Logan of the Cayuga Tribe came to Ohio from the Susquehanna River region in 1770. His life was very hectic. He spent part of his time with the English speaking people and thus was able to speak two tongues but strife, fire-water and destruction were his lot in Ohio. Of the many villages built by the Indians from 1700-1800 all experiences complete annihilation so that not a trace remains in Ohio to show how they built. Likewise nearly all of the structures erected by white men prior to 1800 were burned or ruined by the enemy.

The account of brick uses must therefore deal with the last century. The history of the iron industry in Ohio begins with the erection of a blast furnace at Poland, Mahoning County, a few miles southeast of Youngstown. This furnace was founded in 1806, and began to make iron in 1808. All ores, which produce iron, are mingled with clay seams found lying beneath coal veins. Shortly after the Civil War Ohio was producing more iron, with the exception of Pennsylvania, than any state in the union. The iron producing era in Ohio extended to 1885. Since the growth of the brick producing age is part and parcel of the iron age it is appropriate that we deal with iron ore production in the Hocking Valley. The early charcoal blast furnaces were:

1852 Hocking Furnace, near Logan_____ Hocking Iron Company

1855 Five Mile Furnace ______________Five mile Furnace Company

1854 Big Sand Furnace_Raccoon Creek__Big Sand Iron Company

1858 Zaleski Furnace________________ Zaleski Iron Company

The native ores are mined at or near the furnaces, either upon the furnace property, or are brought in by farmers upon whose lands the exposure occurs, and who during such time as they can spare from the ordinary work of their farms, dig ore in small amounts and bring it to the furnaces. The coal measure ores, forming beds from a few inches to some feet in thickness, crop out along the hill-sides over this region. The extent to which the hill can be worked into will vary with its steepness but does not exceed 20 or 30 feet. - "Orton-Economic Geology" 1884.

Later Charcoal or coal furnaces of the Hocking Valley were:

Place Name Date Size or Dimensions

Union Furnace Union Furnace 1853 32 X 10

Logan Logan 1852 29 X 9

Oreton (Vinton) Eagle 1852 32 X 11

Gore Baird Furnace 1874 44 X 11

New Straitsville Bessie Furnace 1877 60 X 14

Shawnee Mollie Furnace 1877 50 X 14

Shawnee Fannie Furnace 1874 50 X 12

Shawnee XX Furnace 1876 50 X 14

Greendale Crafts 1879 58 X 15

Orbiston Helen Furnace 1877 52 X 15

Monday Lee Furnace 1877 52 X 14

Gore Gore Furnace 1876 47 X 12

Winona (Hocking Co.) Winona Furnace 1878 50 X 12

Buchtel Akron Iron Co. 1872 60 X 16

Floodwood Buchtel Furnace 1882 60 X 16

The disappearance of the forests under the demands of the furnaces which is now (1884) so apparent throughout the region, increases every year the difficulty of obtaining the necessary fuel, and marks very plainly the fate of the charcoal iron industry. (Orton) {Explanation: trees were chopped and burned into a type of charcoal which was used to heat the furnaces which cooked the iron so that it could be made into small shippable ingots. This totally wiped out the forests of the Hocking Valley as each furnace could easily burn 80 acres of trees in a year. As the areas ran out of this handmade charcoal, the discovery of bituminous coal was important as it became the next fuel for the iron furnaces.}

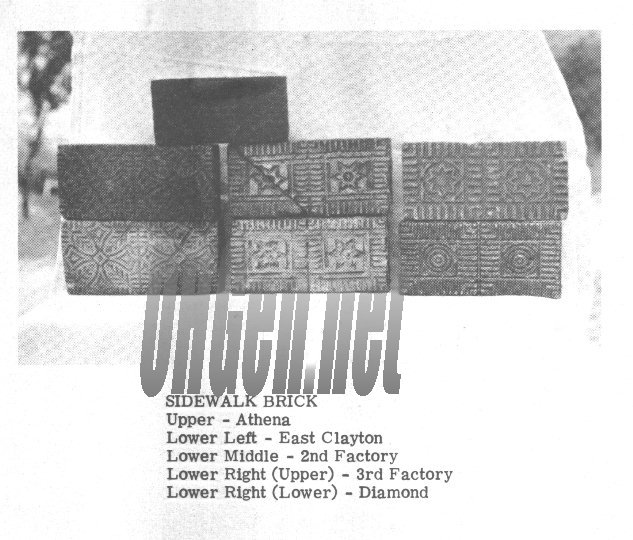

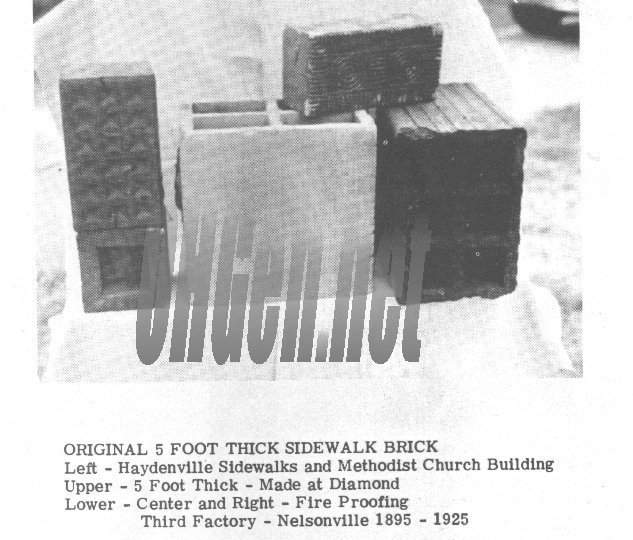

Two things resulted, in the first place brick was needed to build the furnace in the event that proper stone was not available and stone is always expensive to buy, to transport and to place in a building. In the second place, the search for iron revealed the natural resources of clay and coal which resulted in "wealthy " golden age of 385 railroad coal mines and at least 17 immense clay factories. The iron boom brought men and money from all parts of the world. The Hocking Valley in 1870 was a dawning of a new day. We now will study the past, concerning Nelsonville, with regard to sidewalk brick, building brick, paving brick and sewer tile.

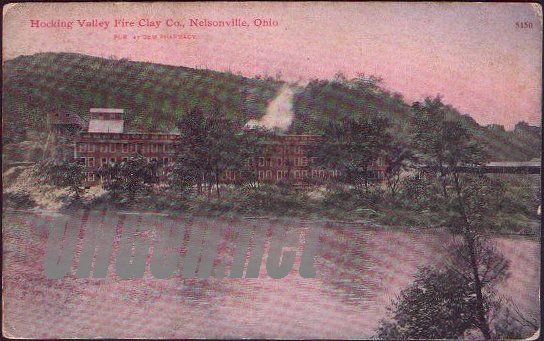

"Nelsonville, O" Is In The World Forever

You may destroy this city- Nelsonville, Ohio - but you will never be able to take it out of the world. In it's heyday the Hocking Valley around Nelsonville produced brick which is imperishable, made from Number 5 fire- clay, repressed solid brick, properly and expertly pugged or mixed, dried and seasoned in expensive sheds- under talented qualified inspectors-, burned in kilns at a temperature of 2000 degrees temperature by men who had been trained by their fathers and salt glazed by shoveling salt into the fire box at high temperature, this product is unchanged after fifty, sixty and seventy years, "The Neon Bock" "Nelsonville Paver" "Hallwood Block" and "Athena" may be seen on streets, sidewalks, alleys, or the "Building" brick may be seen in every large city in this country and in many places abroad.

Some of the large manufacturing companies were "Hocking Valley Products Company" located at Greendale, Ohio north of Nelsonville; "Athena" located in Nelsonville; "Nelsonville Brick Company", Nelsonville; "Diamond Brick Co." west of Nelsonville; "East Clayton Brick Company.:, 6 miles west of Nelsonville; "Logan Clay Products", Logan Ohio; "Hocking Brick Company", Logan; "The Columbus Brick and Terra Cotta Co." Union Furnace; "The Straitsville Brick Co." new Straitsville; "The Wassall Brick Co.", Glouster, Ohio; "The Trimble Brick Co." Trimble, Ohio; and "The Athens Brick Co.", Athens, Ohio.

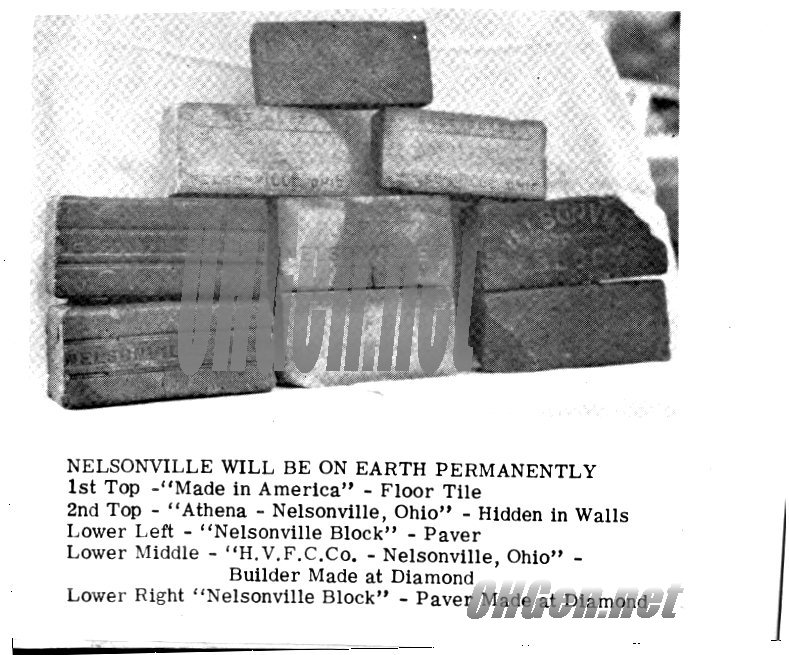

There are three clay industries in existence in this area today (1968). They are "The Glen Gery Corp." three miles west of Nelsonville; "The Logan Clay Products", Logan and "The General Hocking Co.", Logan, Ohio.

Brick making in Ohio was coincident with the iron furnaces and the great Hocking Valley brick making age followed immediately the closing of the iron age here. Nevertheless, prior to the Civil War, bricks were made in Ohio and Indiana much the same way as they had been made in New England, Germany and the British Isles for hundreds of years. Brick makers were recognized master craftsmen who took part in the Grand Federal Procession in Philadelphia on July 4, 1788. As pioneers pushed west from the Atlantic seaboard, some of them took the traditional techniques of brick making with them. (Susan Carter - "Star Brick Sidewalks of Elwood, Indiana") Malvern Wilson gives a graphic description of a one- man brick operation in Nelsonville in the 1830's found in the Parade of the Hills book- 1965)

In Nelsonville the brick Hotel Dew was put up in 1839 and the first brick school building completed in 1856. In Athens at the heart of Ohio University is Cutler Hall, built in 1816. These early buildings were constructed of "Soft Brick".

The extensive paving of city streets with brick manufactured for the purpose began in this country in 1870, at Charleston, West Virginia. In 1873 a block of a principal street in that city was laid with "good quality brick", and was reported in service 29 years later in 1902. By the later date, Philadelphia led all the cities in the country with over 135 miles of brick - paved streets. If it is possible for one to wax enthusiastic about bricks in the manner that others admire classic automobiles of firearms, The Nelsonville Block would seem to merit consideration as the king of pavers. There is a certain purity about it's dimensions, lines color, and sleek glazed surface. It's measurements are larger than the standard dimensions for pavers....an estimated specific gravity of approximately 2.46...dense as crown glass...big, heavy rugged, durable Susan Carter "Star Brick Sidewalks". The last pavers made in Nelsonville was in 1937 when Washington and Chestnut streets were paved. Many of our city streets, as well as the public square, were paved by 1900 or soon after. The sidewalks of "star" brick were paved earlier since mid - America began to make sidewalks before they began to build brick streets and highways.

Nelsonville's Present Brick Industry (1968)

|

|

|

|

This factory is owned and operated by the Glen Gery Corporation of Reading, Pennsylvania and is located on Route 33 a tthe Diamond west of the city limits. No. 4 fireclay is stripped and mined from the Fred Wolf farm, formerly known as "The Cox Farm", and "The Cable Farm" which is near to the city limits and is in Hocking and Athens Counties.

The Diamond Brick Plant was built in the period of 1911 by four Nelsonville men:- Martin Ohlinger, John Reiter, "Hud" Price and James Pealey for the purpose of manufacturing fire proofing tile. Some years later the New York Coal Company interests purchased it and they in turn, after a few years, sold the plant to NATCO- a nation wide concern, in 1967 the Glen Gery Corporation purchased it.

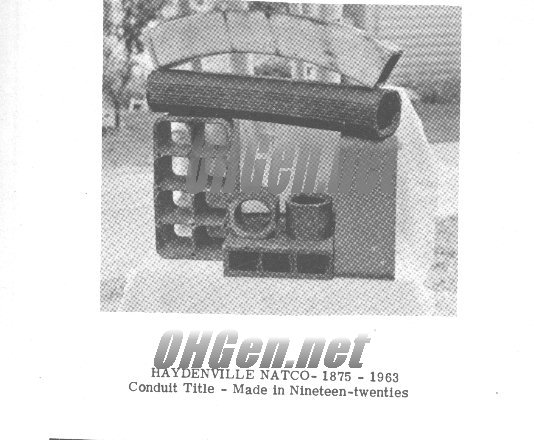

NATCO (the former Haydenville Firm) were manufacturers of Conduit Tile for Western Electric Co. These were used to carry telephone, telegraph and electric wires underground and were shipped to all parts of the nation. They from 1912 to 1916 built silo tile which was used on farms from New York, Michigan, Wisconsin, Indiana and Ohio. Structural tile Tex-Tile were used for small and large buildings such as garages, stores, elevators, manufacturing industries and theatres.

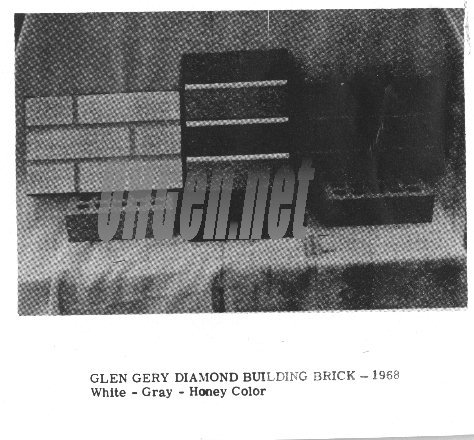

During this season The Diamond moved the making of brick- normal and standard for beautiful homes, hospitals, school buildings etc. and was able to produce the colors and facing of the former rug faced brick of Greendale fame and Athena light brown. Colors in brick are attained during burning by withholding oxygen for dark colors and adding oxygen to get light colors. The color of Nelsonville clay when burned is toward a light brown clear color and is famed as it has been for n early a century. Glen Gery has succeeded in producing the gray natural clay color which was made famous by the Union Furnace Brick Company which used No. 3 fireclay but ran out of clay and also Glen Gery is producing a white colored brick to be used as all their products are either for the interior or exterior of rooms and artistic buildings.

At the present Glen Gery is shipping Nelsonville brick to Maine, New York State, Massachusetts, Pennsylvania, Florida and may other states as did the early manufacturers here.

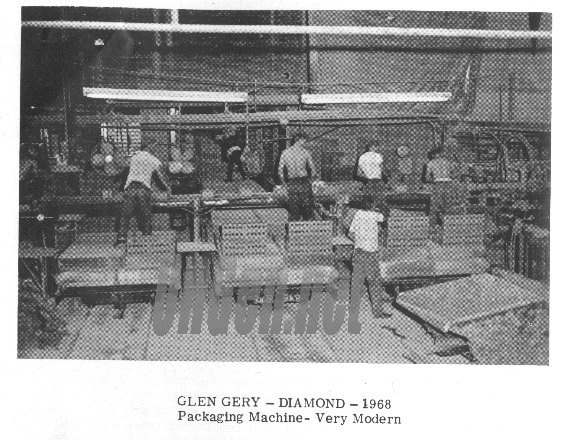

The picture of the inside of the shed at the Diamond on the front page of this Parade of the Hills booklet shows an ultramodern machine packaging the brick and in the background men off bearing brick. The product is touched but once by human hands. 58 men do the work of several hundreds in this age.

The reader has by now surmised that the No. 4 Fireclay of Nelsonville is a very valuable natural resource. The past is impressive but one must see that the future has much in store for it. The clay here is of a superior quality. The author had the opportunity to see the best clay yet. This has never been used with the exception of several tons for experimental tests. Lying in the hills between the Fulton Street Bridge and Floodwood on the south side of the river is No. 4 Fireclay sixteen feet thick and nearly free from iron pyrites.

Near the Yorde Manufacturing Company building the surface soil is difficult to even spade. It do not know but I will guess it is No. 4 Fireclay. Our youth should experiment with these clays.

I have listened to the old timers tell in enthusiastic terms about the ABSOLUTELY WHITE CLAY found east of the Baird Brothers cattle barn. Fred Coakley, during his life, spent many hours telling about it. Dow Shafer, during his life, described this alabaster clay in the hills south of the new Vocational School. It is well that the coal mines are closed and that we have not developed this clay yet. Perhaps it is well. Maybe we don't know enough to use it.

At least we are delighted that Glen Gery are producing products as good and perhaps better than our talented forefathers did.

"THE STAR BRICK OF ELLWOOD, INDIANA" - an eighty-two page thesis about Nelsonville clay and brick may be found in the Nelsonville Public Library, The Hocking County Library at Logan and The University Library at Ohio University, Athens, Mr. Evans assisted the author, Mrs. Carter. We suggest you read this. These are the only places it is to be found. Mr. Evans has the original, a gift from Mrs. Carter.

Historical Brick Plants

1. The East Clayton Brick 1870. This factory was located three miles west of Nelsonville on the south side of the Hocking River. The operational machinery and building were destroyed by fire in 1892. Some of the kilns and smoke stacks are still standing. I would judge this to be the first modern (brick burned at 2000 degrees) in the valley. They made sidewalk and paving brick. We think this plant was owned and operated by Eastern Capital and Columbus Ohio finance.

2. The Haydenville Brick Companies 1875-1963. Peter Hayden, a man interested in iron furnaces, owned 3000 acres of land, underlaid by rich deposits of coal and fireclay, on the north side of the Hocking River 6 miles west of Nelsonville. He developed and established the Haydenville Mining and Manufacturing company turning out immense quantities of sewer pipe, fireproofing, terra cotta, and paving block. He built houses for employees and named the town of Haydenville. Hayden lived in Columbus and died in 1888.

3. The Columbus Brick and Terra Cotta Company 1897-1921. L. G. Kilbourne was president and general manager of this manufacturing plant in 1901. They used No. 4 fireclay to make Standard Roman, Norman and Ornamental brick in Buff, Gray, Terra Cotta, Buff Speckled, Red and Mottled Enameled, Brick mantels were a specialty. Kilbourne lived in Columbus, O. This plant was located at Union Furnace, Ohio 2 miles south of Haydenville.

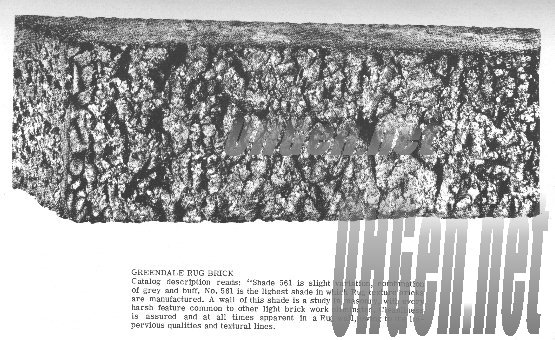

4. Hocking Valley Products Co. 1902-1927. I surmise that this huge development was made by the well known capitalist Kachelmacher. Face brick was a rug type finish manufactured from No. 5 fireclay. The quotation from Ruskin "Therefore, when we build, let us think that we build (public edifices) forever" was carried on all their advertising. This clay works was at Greendale, Ohio - 6 miles north of Nelsonville. Look for these Greendale brick building while you travel -- They are: The Deshler Hotel, Columbus, O., Loyola College, Montreal; McFarland Building., Vancouver British Columbia; Penn Valley Park Field House, Kansas City, Missouri; Kennington Residence, Jackson Mississippi; Wm. H. Boutell residence, Bay City, Michigan; St. Stephens Church, (Catholic) Toledo, Ohio; Knight Building, Jacksonville, Florida. Continuing the quotation from the 1920 advertisement: "Let it be such work as our descendents will thank us for, that a time is to come when those bricks will be held sacred because our hands have touched them, and that men will say, as they look upon the labor and wrought substance of them, See! This our fathers did for us". The Hudson River tubes were build of the brick from Greendale.

(Greendale famous rug brick)

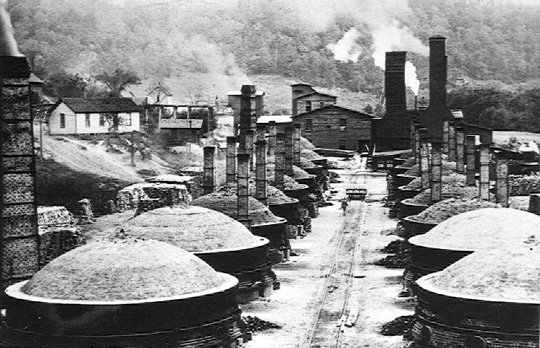

(Greendale brick furnace- photographer Sandra Mitchell Quinn)

5. The Wassall Brick Co. The Wassall Brick Company of Columbus, Ohio with a medium sized plant at Glouster, Ohio operated during the early one fourth of this century producing paving brick, building brick and sidewalk brick from shale.

6. The Trimble Brick Co. The Trimble Brick company was owned and operated by a coal company. It was located at Trimble, Ohio and manufactured paving brick, sidewalk brick and some building brick. It had been operating several years by 1904. The plant was on the road side by the stone cliffs at the edge of Trimble going toward Amesville. The brick were shale made from ground stone.

(Trimble Brick Plant- photo from Athens county historical society)

7. The Athens Brick Co. Brick has been manufactured in Athens from 1815 till about 1920. Cutler Hall was erected in 1816 with brick made close by to the present seen structure. In 1867 an order was let for 12 million brick for the first structure of the Athens State Hospital-- these were soft brick and were produced on the grounds. The lakes on the grounds were later made from the pits caused by taking clay from the site. After the first building the contracts were given to Mr. Henry O'Blennis (father of Charles O'Blennis) of Marietta, Ohio who moved to Athens when he secured the contract for the second building. All later building in the last century were made and erected by him. In about 1895 wagons and carriages were, during rainy weather, becoming mired on Court Street in downtown Athens. This demanded the paving of city streets and the Athens Brick (paving) Company was ready for them. The relationship of clay plants is an involved one. Dr. William Alderman of Nelsonville, Mr. Charles Doan and his son Robert Doan, Mr. Fred Stalder of Athens County and Mr. Henry O'Blennis of Athens formed a Brick Company but lacked money for operating capital therefore the City of Athens advanced $20,000 to them on the provision that the money would be repaid in brick. This was done and the plant operated til about 1920. It was where the present A & P Store is in Athens.

Athens State Hospital built by Mr. Henry O'Blennis

8. The Nelsonville Brick Co. 1880-1937. Makers of the "king of all bricks" - The Nelsonville Paver- The Hallwood Block - The Hocking Paver - The Star sidewalk brick. This company kept the railroads busy carrying their product far and wide. You if you are observant may find these brick in Niagara Falls, N.Y., in Philadelphia PA, in cities in Indiana, on platforms of stations, in Chicago and as you ride over the asphalt roads and streets beneath you in Nelsonville is the original road bed of Nelsonville.

9. Repress, Solid No. 5 Fireclay Imperishable Brick. This No. 2. plant as it was known because it was between Jewett's Athena and No. 3 Fireproofing plant was located where the charcoal plant now is on the south side of the river in Nelsonville. Local men's names are associated with it; Bob Doan, Wilson, Murphy, Billy Evans, Ed Cramner, Dr. Hyde, W. H. Parks, and all others who worked there.

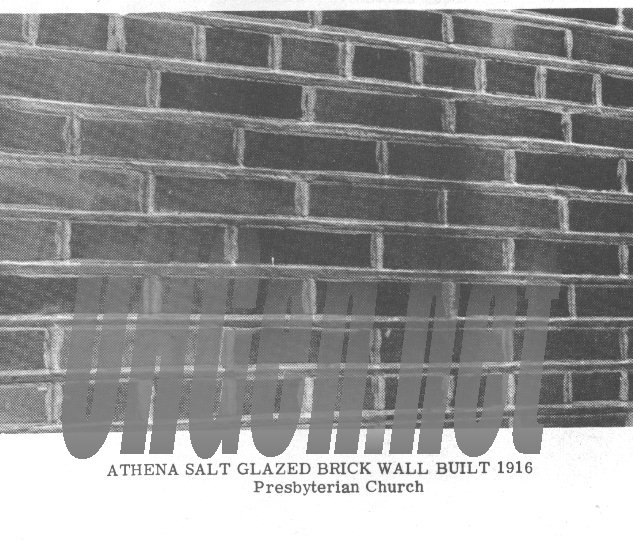

10. The Athena Glazed Brick Corp. 1905-1927. A product of one man's mind- Mr. Carl Jewett. This plant was where the Veterans of Foreign Wars home is now. No. 4 Fireclay mined with powder out of the seam under ground was pugged, dried, shaped, burned by experts and shipped to all parts of the nation and to many foreign places. Interior finishes in the Mellon Museum in Washington D. C. and many other places in the nation. Exterior brick with which the mortar is the only part that can wear out. Walls to which neither vine nor paint will cling. Look at the Peoples Bank or the rear rooms of the Presbyterian Church then as you travel look for Nelsonville brick buildings.

11. The Nelsonville Fireproofing Company. This plant stood where Dale Wharton has leveled the ground on the extreme west end of Nelsonville across the river. This production was hollow-title to place between walls of big buildings so the heat and cold could not penetrate and to keep fire from the interior of a building adjoining one that might be destroyed by fire. This company I would say lasted about ten years and was evidently built after the New York Coal Company and E. M. Poston became interested.

12. The Logan Clay Products Co. The Logan Clay Products Co. celebrated it's 75th anniversary last year (1966). It has been in continuous operation during that time. It ships sewer tile, which is also made with fireclay, Wisconsin, Illinois, Indiana, Michigan, Kentucky, West Virginia, and Ohio. This operation has the latest and most modern machinery and methods of making tile from clay. The plant is within the city limits of Logan, Ohio 12 miles west of Nelsonville, Ohio.

13. General Hocking Brick Company is located at Logan Ohio. It manufactures building brick and allies clay materials.

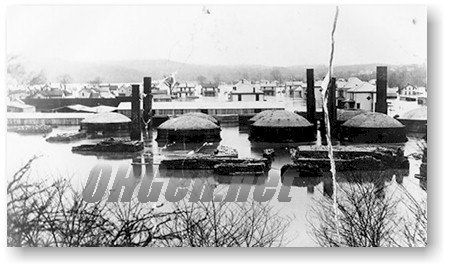

Nelsonville brick factory during flood of 1907

14. New Columbus Clay and Terra Cotta Co. located at New Straitsville, Ohio is active in production.

15. The Glen Gery Brick company, Nelsonville's only active brick company.1911 to 1980 apx.

Photo's from the 1968 Lion's Club Parade of the Hills program booklet, and from the personal photo and postcard files of the webmaster.

This webpage was created by Sandra Mitchell Quinn

for her Athens county, OHGENWEB

copyright 1996-2004 ALL RIGHTS RESERVED